-

Search

-

18046987606

18046987606

Fiona@Robobeen.com

Fiona@Robobeen.com

Overview

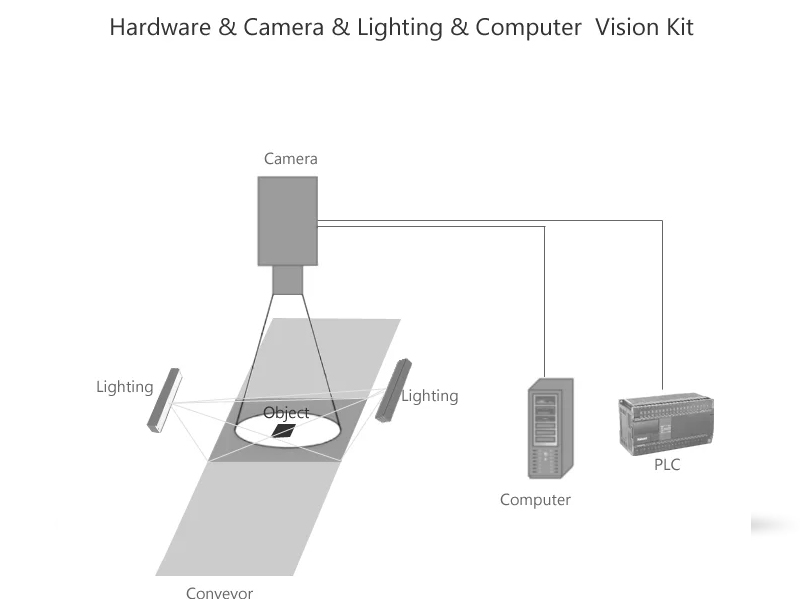

A Visual ID System is an identification system that uses cutting-edge technology that can increase the level of precision, timing, and accuracy when used in industries and commerce. This utilizes operations like cameras, sensors, and software to both capture, process and interpret Visual-data for example, Barcodes &-QR codes, labels, logos, etc. The primary use of a Visual ID System is when identity needs to be confirmed or identified without much interference from the human element.

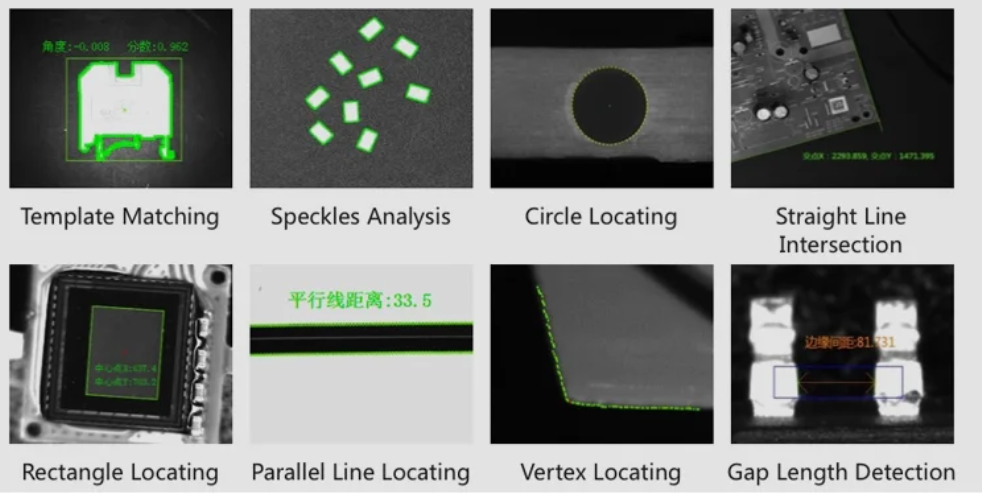

Positioning

An efficient positioning tool can accurately and quickly find the position of geometric objects such as circles, lines, spots, edges, and vertices, overcoming differences caused by sample translation, rotation, zoom, and illumination. It provides location and presence information useful for robot guidance and other vision tools.

Applications

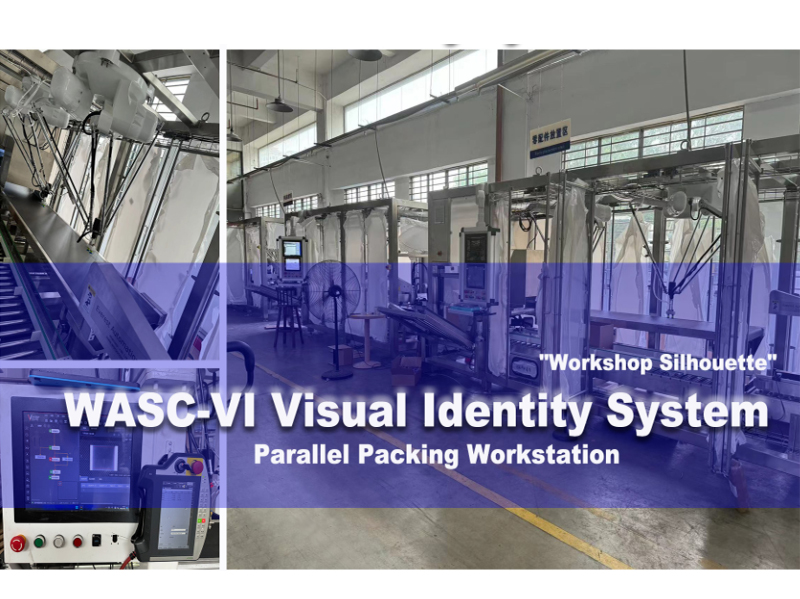

● Manufacturing: Applied to the assembly line to help recognize the parts and products so that they can be well handled and processed correctly.

● Logistics and Warehousing: For instance, it is used in extensive storage facilities to sort items quickly and conveniently, making it easier to manage inventories and minimizing mistakes when fulfilling orders.

● Retail: It helps to check the authenticity of the products, control the scale of thefts and losses in real-time, and increase confidence in purchases.

● Pharmaceuticals: It ensures that the correct products are properly classified, packaged, and labeled to comply with industry standards.

● Food and Beverage: Identifies and monitors products as they go through the supply chain and checks on their quality and origin

Features

● High Accuracy: It helps identify items appropriately, thus reducing the possibility of confusion while sorting, packing, or processing the items.

● Real-Time Processing: It can analyze visual data and make interpretations immediately with the capability to work in short periods and respond to automated systems.

● Customizable Solutions: The Visual ID System can be explicitly oriented to specific fields: identification of goods moving on the conveyor and checking the authenticity of products in the possibility of their forgery in the sphere of trade.

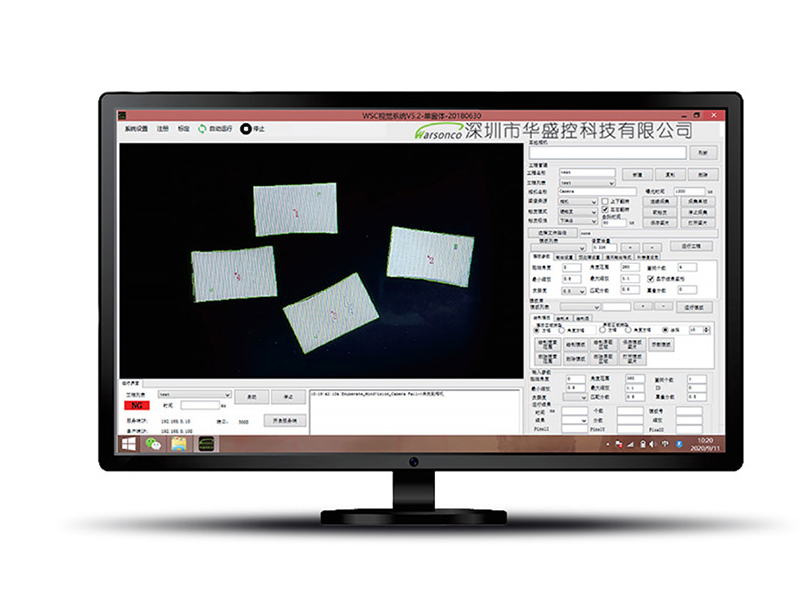

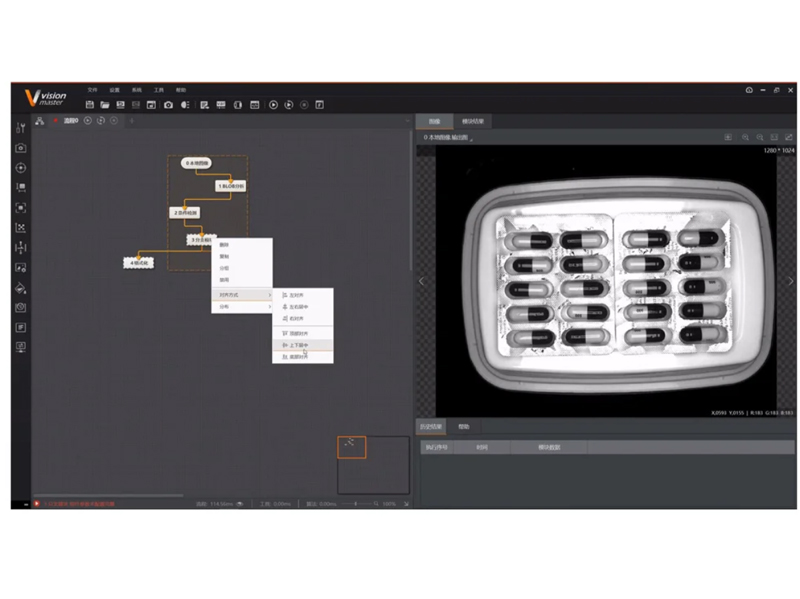

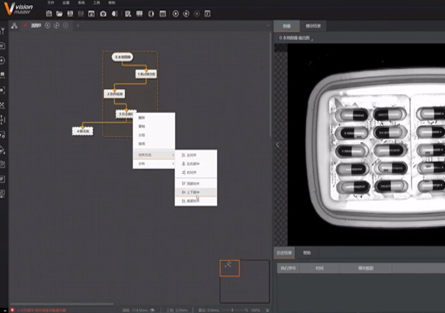

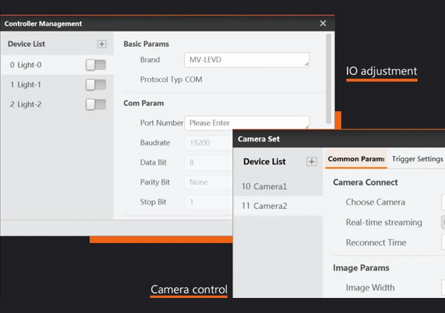

● User-Friendly Interface: Features and an easy-to-use interface enable simple configuration of the oven, making it easy to operate by persons with little technical inclinations.

● Scalable Integration: Compact enough to be installed into standalone schools, faculties, production lines, and manufacturing facilities, both big and small.

●High-Speed Operation: It is ideal for a high-speed environment so that identification processes can continue with the speed of the production line.

● Robust Design: They have been designed and constructed to survive in harsh industrial climatic conditions, hence their durability and reliability.

Specifications

| WASC-VI visual identity system | |||

| Development language | C++/Halcon | Models | M0814-MP2/M1214-MP2/M1614-MP2 |

| Compatibility | Support most of the image acquisition equipment on the market | The software supports the operating system | WIN7/10 (32&64-bit system) |

| Development environment | QT | Date Protection | Multiple user level permission settings |

| Sensors | 1/3 CMOS | Camera Type | Black and white /Color |

| Effective Pixels | 1.22Million/5.02Million | Shutter Type | Global shutter |

| Visual Software | GigE vision V1.2,genlcam | Resolution@Frame Rate | 1280*960@60.6FPS/2592X2048@22FPS |

| Network Card | 2 Gigabit ports | Acquisition Model | Continuity/soft trigger/hard trigger |

| Type | LED Strip/Strip light source | Lens Interface | C Interface |

| Data Interface | Rj45 gigabit ethernet interface, down compatible with 100m network standard | ||

| Function | Supports custom resolution for any size ROI, contrast and gamma adjustment, saturation adjustment, white balance correction, black level correction, custom dead pixel correction, ISP image processing acceleration, 3D noise reduction, custom LUT table, frame rate adjustment, custom camera name, and more. | ||

| Maximum Picture Size | 8.8mm*6.6mm | Focal Length | 8mm/12mm/16mm |

| Maximum Aperture Ratio | 1:1.4 | Control | Aperture:manual/Focus:manual |

| Interface | C interface | Processor | I5-3570 |

| Scope of Work | Aperture: F1.4-F16C, Focus:0.1m-inf. /0.15m-inf. /0.3m-inf | ||

| Operating Temperature | -10~50℃ | Compatible with Motherboard Type | ATX standard |

| Models | IPC-610H | ||