-

Search

-

18046987606

18046987606

Fiona@Robobeen.com

Fiona@Robobeen.com

Overview

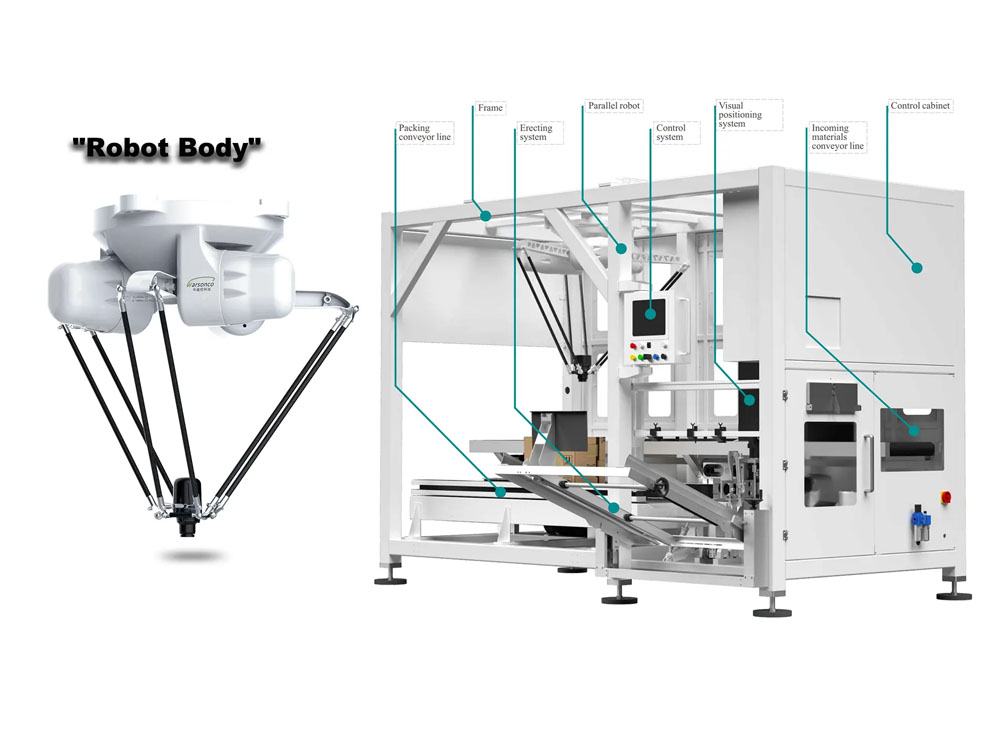

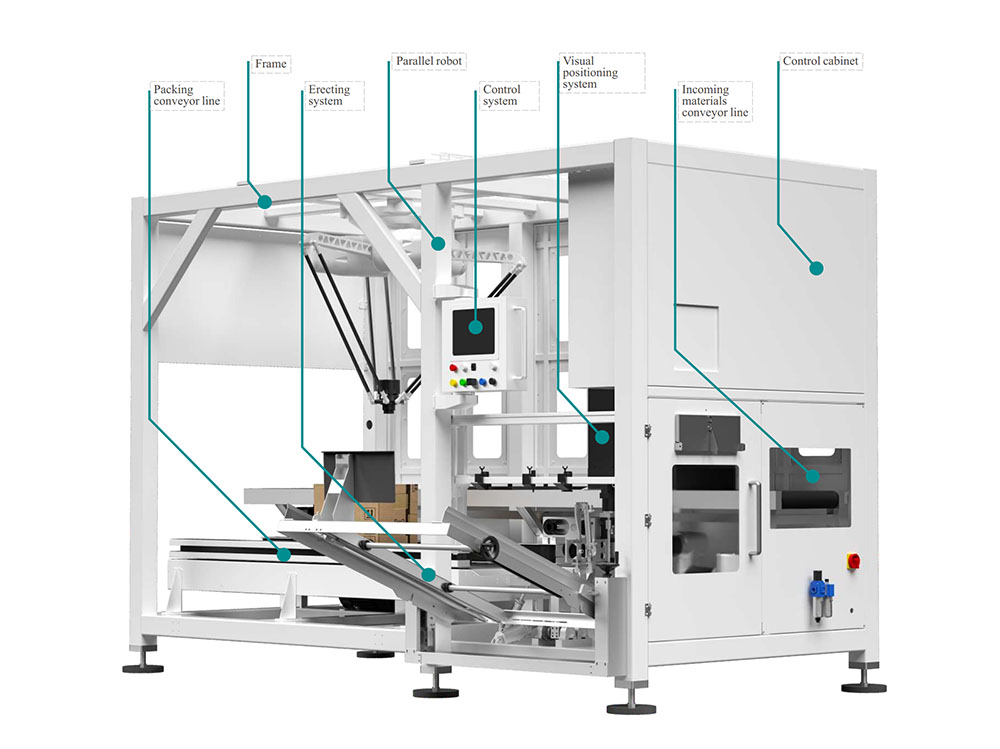

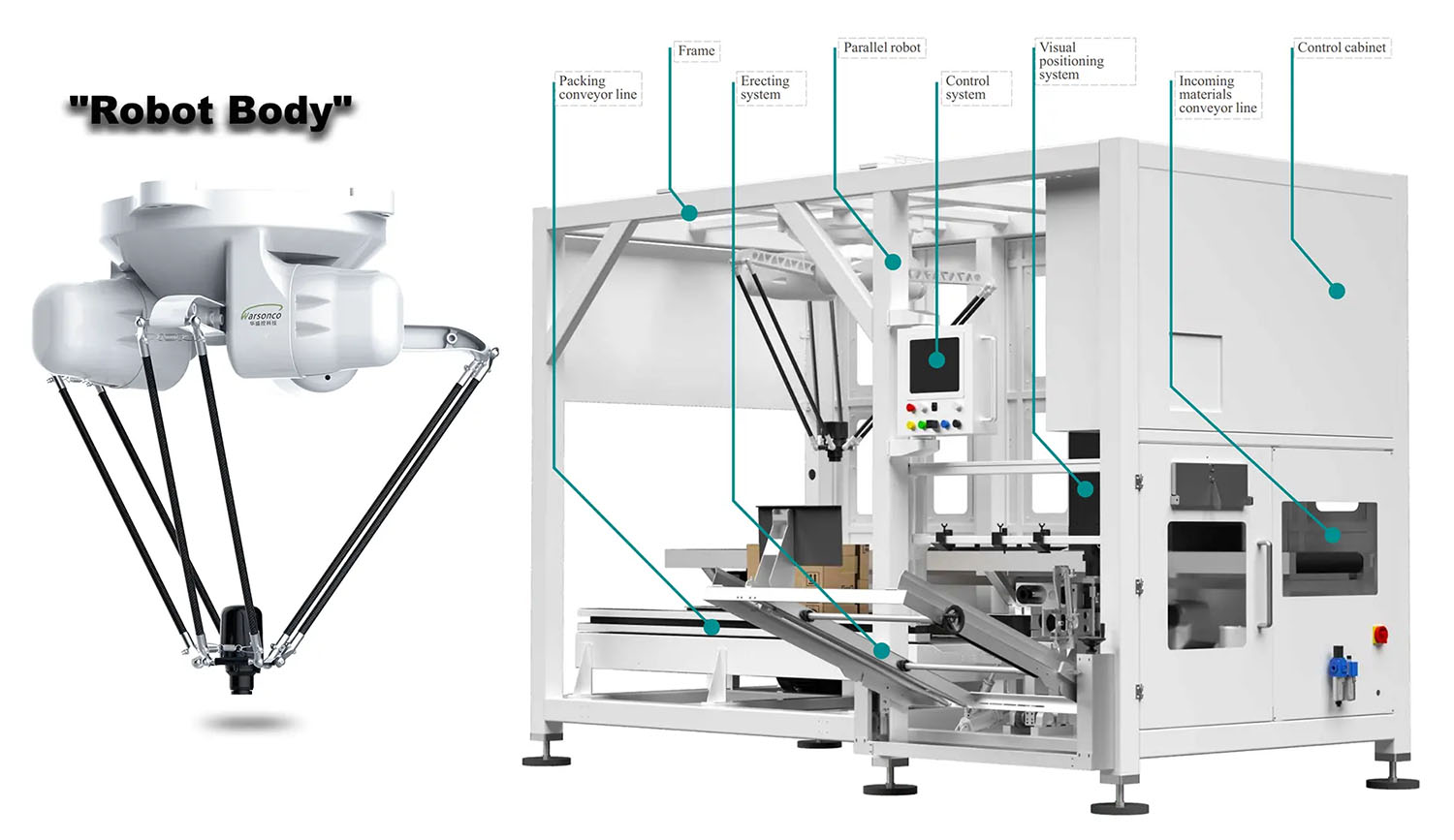

Introducing the Robotic Case Packing Machine by Robobeen which is a smart case packing solution that combines unpacking as well as packing capabilities. Prone to automatic installation and usage, this equipment has a small size and high integration of structures so as to be suitable for facilities with small space available. Safe to use, with a very short pacing line and extremely automated, this machine is ideal for industries that have strict measures needed in packing such as the food industry and the pharmaceutical industry.

This equipment has one of the most flexible control technologies that are on the market today. Through the flexible application of recipe management and the more user-friendly layout, operators can rapidly control and select a multitude of packaging systems saving a considerable amount of time on converting line layouts to increase productivity.

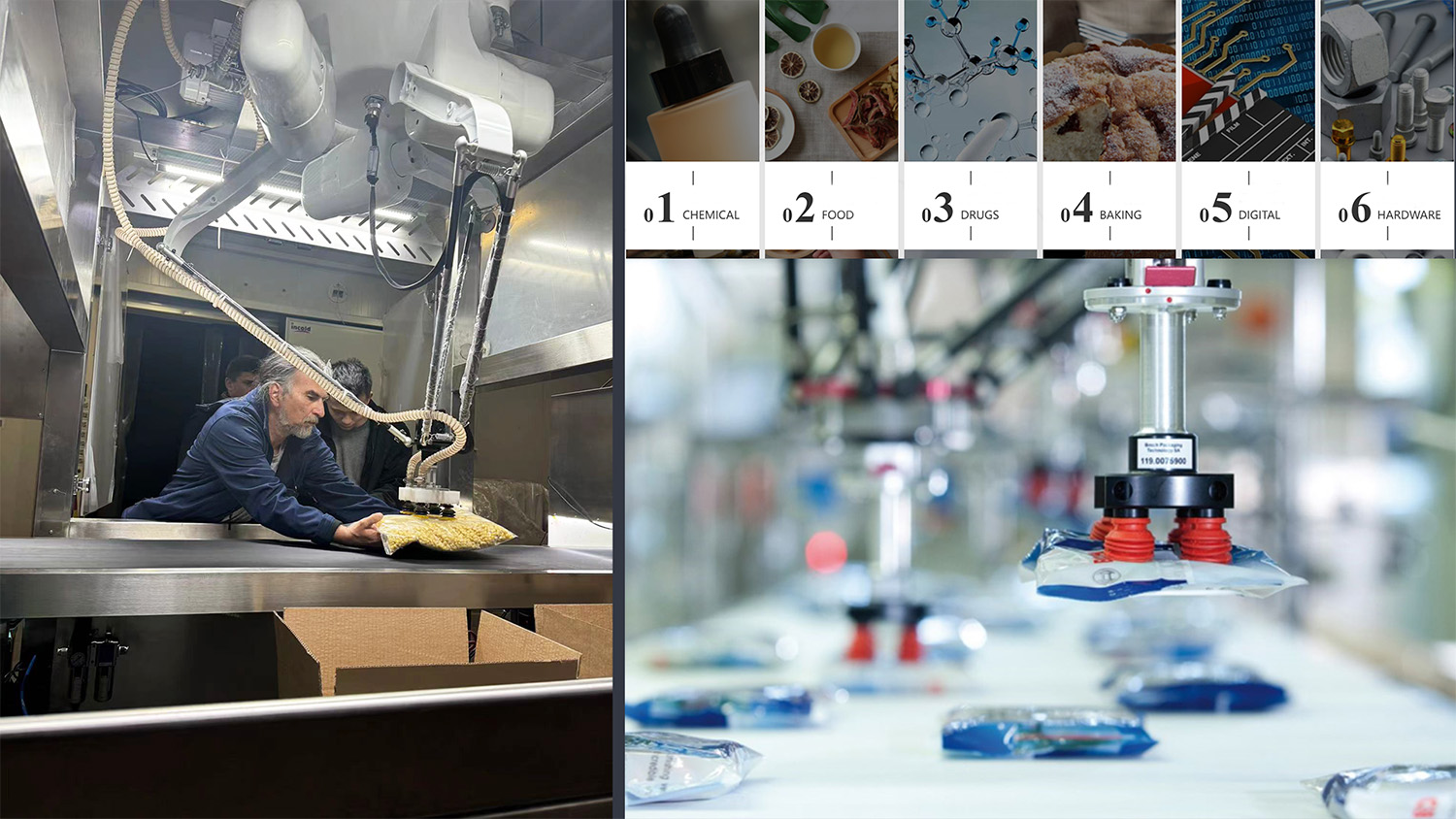

Applications

The Robotic Case Packing Machine is highly versatile and finds application across multiple industries:

● Food Industry: Convenient for containing food products including; snack foods, bakery products, frozen foods and any other food you want to package safely for distribution.

● Beverage Industry: This effectively deals with stocking and storage of different types of containers used in beverages with special attention on how they can easily occupy space and maintain the stability that is essential when they are being transported.

● Pharmaceutical Industry: Emphasizes on accurate and secure method of contains the fragile pharmaceutical products as well as preserving their qualities until the delivery.

● Consumer Electronics: Ideally suited for packing electronic parts and gadgets thereby giving a guarantee that they are well packed to avoid any damages during transporting.

❝ Robobeen has local team providing door-to-door services in South Asia, Southeast Asia and North America.❞

Advanced control technology is utilized to greatly enhance equipment flexibility. Through recipe management and visual design, multiple different packaging schemes can be flexibly set, with one-click switching, significantly reducing production line changeover time and improving work efficiency.”

| Configuration | |

| Servo Driver | Warsonco |

| Controller | Keba |

| Reducer | Laifual |

| Pneumatic System | Air TAC |

Product Features

● High Speed and Precision: The machine runs at high speed with optimum throughput of up to 120 PPM hence protecting the efficiency threshold of the production line.

● Simple Operation: The operation is conveniently facilitated such that even modifications are made via the software to suit various material and packaging solutions.

● Seamless Integration: It can be easily installed into current mechanical machinery and assembly lines thus increasing productivity of the whole process.

● Intelligent Vision System: Is equipped with automatic positioning and tracking with independent gripping including automatic error correction for greater precision and yield.

● Modular Design: The parallel structure is also modular providing additional flexibility and easy installation with small space requirements to suit numerous manufacturing applications.

● Easy Maintenance: Simplification of the robot structure decreases the maintenance difficulty and system expenses and increases reliability.

Specifications

| Erecting packing and sealing all-in-one machine /(Case erector+case packer+case sealer) | |||

| Applicable Product Size | L(10-400)mm*W(10-350)mm*H(5-100)mm | Applicable Carton Size | L (260-500)mm*W (250-450)mm*H (150-400)mm |

| Case erection speed | Up to 10 cases/min | 12kw | |

| Main Material | Stainless steel SUS 304 | White baking paint Q 235 | Packing Speed | 60times/min (single robot)120times/min (dual robots) |

| Rated Load | 5kg/8kg/12kg (including the gripper) | Dimension | L4189mm*W2678mm*H2600mm |

| Coordination Robot | WSC-1200D delta robot | Total Weight | 1800kg |

| Applicable Industries | Pharmaceutical, daily use chemical, food and other industries | ||