-

Search

-

18046987606

18046987606

Fiona@Robobeen.com

Fiona@Robobeen.com

Overview

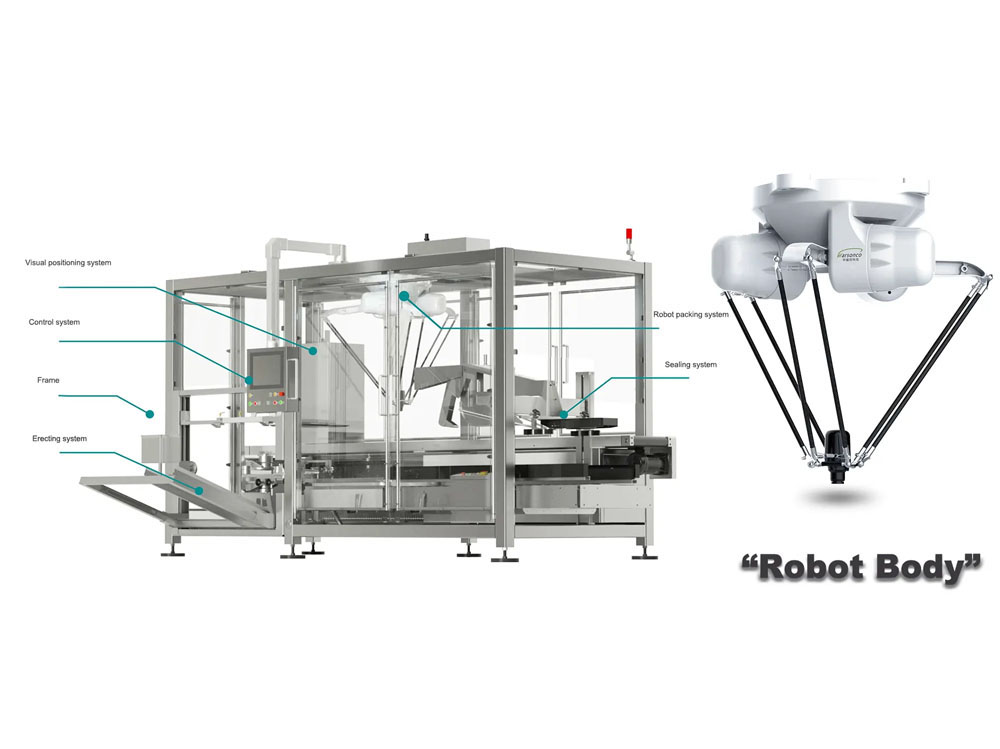

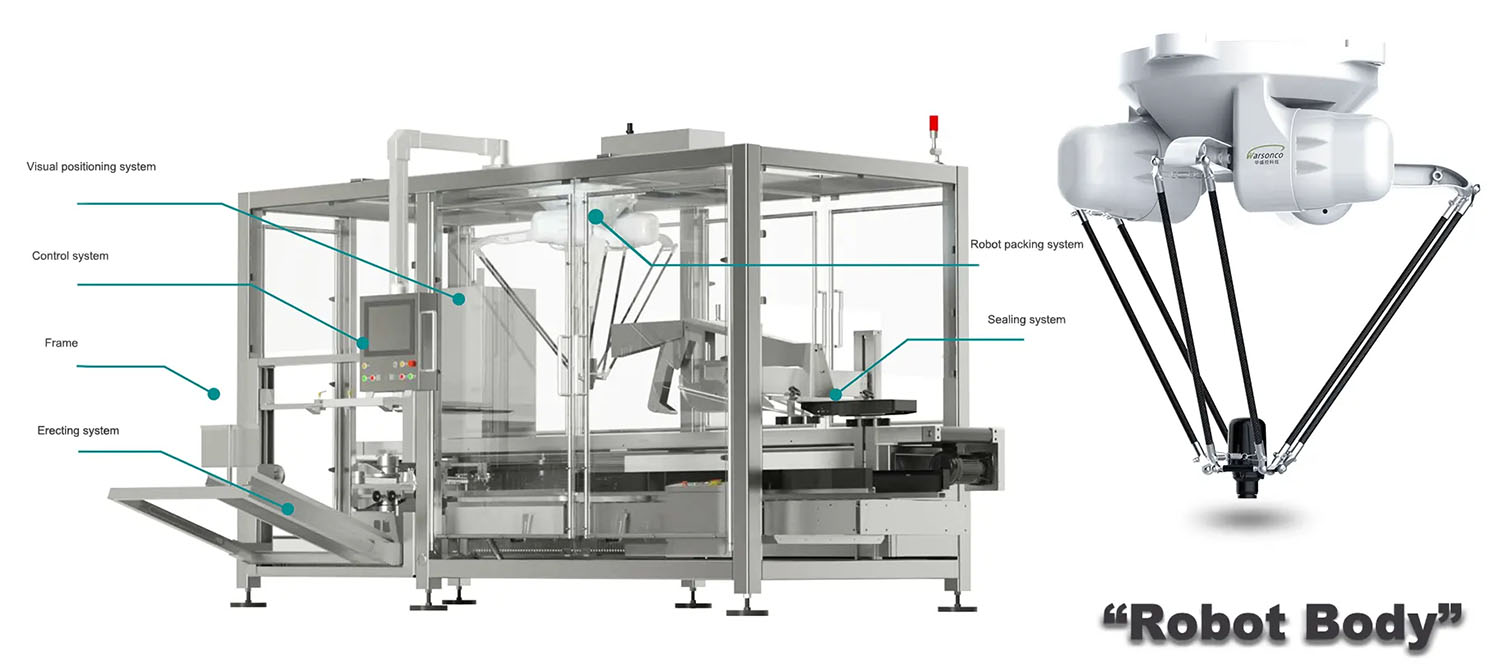

Robotic Case Packer is simply an enhanced automatic tool used in packaging line to pack products in cases or containers. Making use of the latest innovation in robotics, this equipment sort, pack and palletize products of an infinite variety of sizes and shapes into cartons or other types of packaging with increased accuracy.

This all in one functionality consolidates three vital processes of unpacking products, packing and sealing all into one mechanism, which makes it easy to use and install. Due to its compactness and overall integration, it requires the least floor space yet it offers high-speed, high-safety, and a highly automated system. These aspects make the Robotic Case Packer most suitable for use in industries such as the food and pharmaceutical Industries due to precision, speed and safety.

This equipment employs cutting edge control technology so that flexibility to clients is achieved to the highest level possible. The recipe for each batch may be programmed and saved with the help of touch screen; multiple packaging style can be set ahead of time and changes can be made by just the touch of a button which saves time on construction changeover and enhances work productivity.

Applications:

The Robotic Case Packer is versatile, making it a valuable asset across various industries:

- ● Food Industry: Ideal for packing of food stuffs like biscuits, frozen foods as well as bakery products since they ● ensure that the products are well packaged and placed inside the cartons in the right manner.

- ● Beverage Industry: Designed to pack bottles, cans and other beverage containers in the most efficient manner in terms of both compactness and stability during transportation.

- ● Pharmaceutical Industry: Ensures accuracy when packing vulnerable pharmaceutical products which are highly susceptible to alteration when being packed.

- ● Consumer Electronics: Responsible for the correct packing of electronic parts and equipment, and making certain that such product or merchandise are well protected.

| Configuration | |

| Servo Driver | Warsonco |

| Controller | Keba |

| Reducer | Laifual |

| Pneumatic System | Air TAC |

Product Features

The Robotic Case Packer is packed with cutting-edge features that ensure optimal performance in various industrial settings:

● High-Speed Operation: This one has the capacity to process up to 120 packages per minute with due speed and efficiency, making it ideal for organizations, which operate at high production capacities.

● Cost-Effective Solution: Being operating at an optimized manner to also reduce on operational expenditures, this is a system that gives value for money.

● Easy to Operate: Its operating interface is friendly that it does not need much time to be set and it does not take much practice to be operated by the users.

● Modular System: Such modularity makes it easy to add, remove or even transfer functions with a corresponding ease in creating capacity to accommodate different production requirements as well as different layout structures.

● Low Maintenance: Designed with longevity as a key consideration, Robotic Case Packer does not need frequent servicing hence a long lasting machine.

● Certified Quality: The safety of this equipment is therefore enhanced ensuring that it meets the international standards as endorsed by the International Organization for Standardization (ISO) and the European Conformity (CE).

● Advanced Communication Protocols: Modbus TCP/P, EtherCAT, CAN, RS 232/485 varied interfaces are integrated to create compatibility with the existing systems.

Specifications

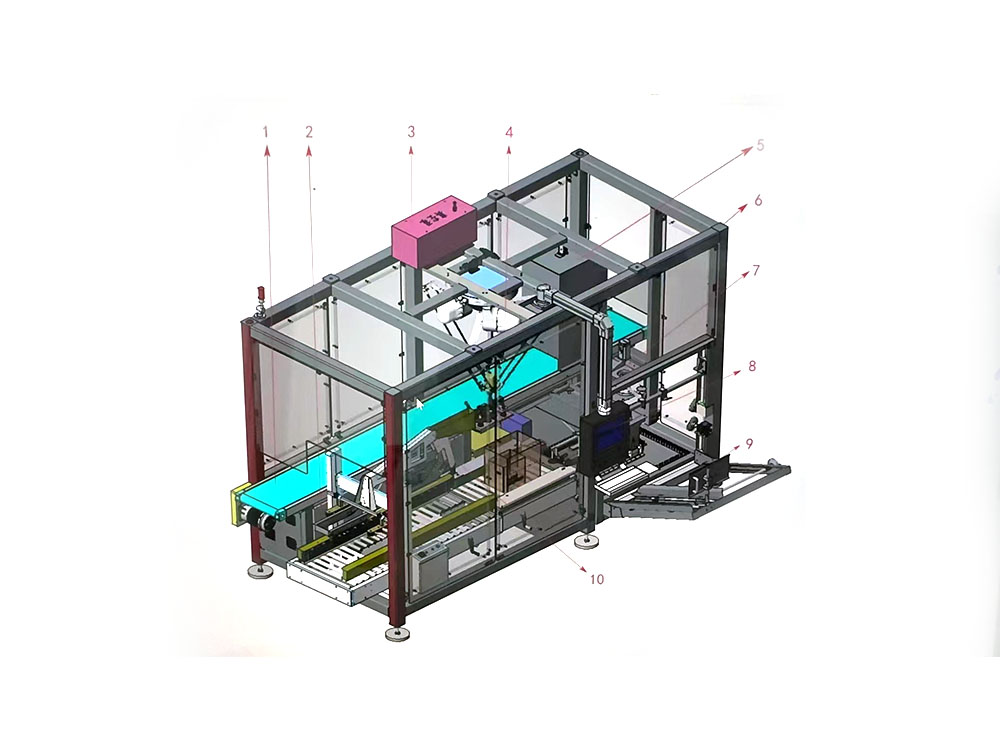

| Erecting packing and sealing all-in-one machine (Case erector+case packer+case sealer) | |||

| Applicable Product Size | L (10-400)mm*W (10-350)mm*H (5-100)mm | Applicable Carton Size | L (260-500) mm * W (250-450) mm * H (150-400) mm |

| Applicable Industries | Pharmaceutical, daily use chemical, food and other industries | Packing Speed | 60times/min (single robot) | 120times/min (dual robots) |

| Main Material | Stainless steel SUS 304 | White baking paint Q 235 | Maximum Power | 15kw |

| Rated Load | 5kg/8kg/12kg (including the gripper) | Dimension | L4189mm*W2678mm*H2600mm |

| Coordination Robot | WSC-1200D delta robot | Total Weight | 1800kg |

| Case erection speed | Up to 10 cases/min | ||