Overview

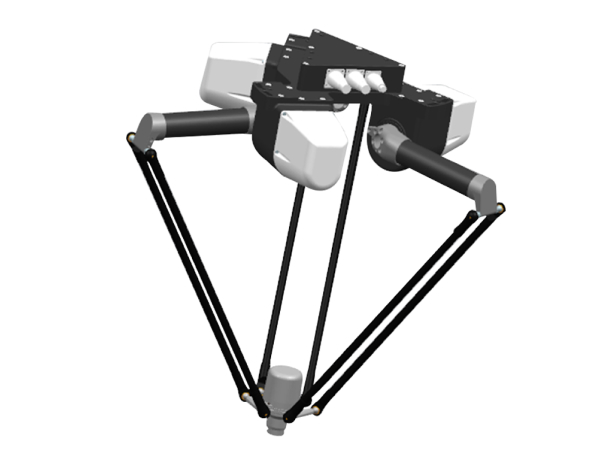

The Delta Robot - ZhiSheng Series (WSC 600DJ/800DJ/1000DJ) is a high-speed, precision automation solution designed to meet the demands of modern production environments. Engineered for efficiency and versatility, this series is ideal for applications in industries such as food and beverage, pharmaceuticals, and consumer electronics. The Delta Robot offers a modular system, easy operation, and low maintenance, making it a cost-effective choice for businesses looking to enhance their production capabilities.

| Configuration |

| Settings |

Brand |

| Servo Motor |

Warsonco/Panasonic |

| Machine Reducer |

Nidec corporation/green |

| Controller |

Austria KEBA |

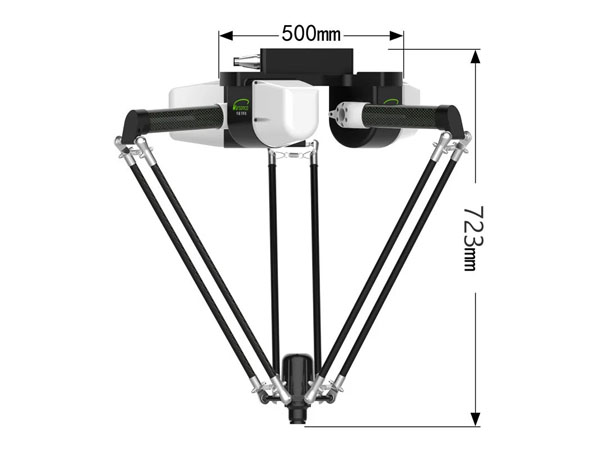

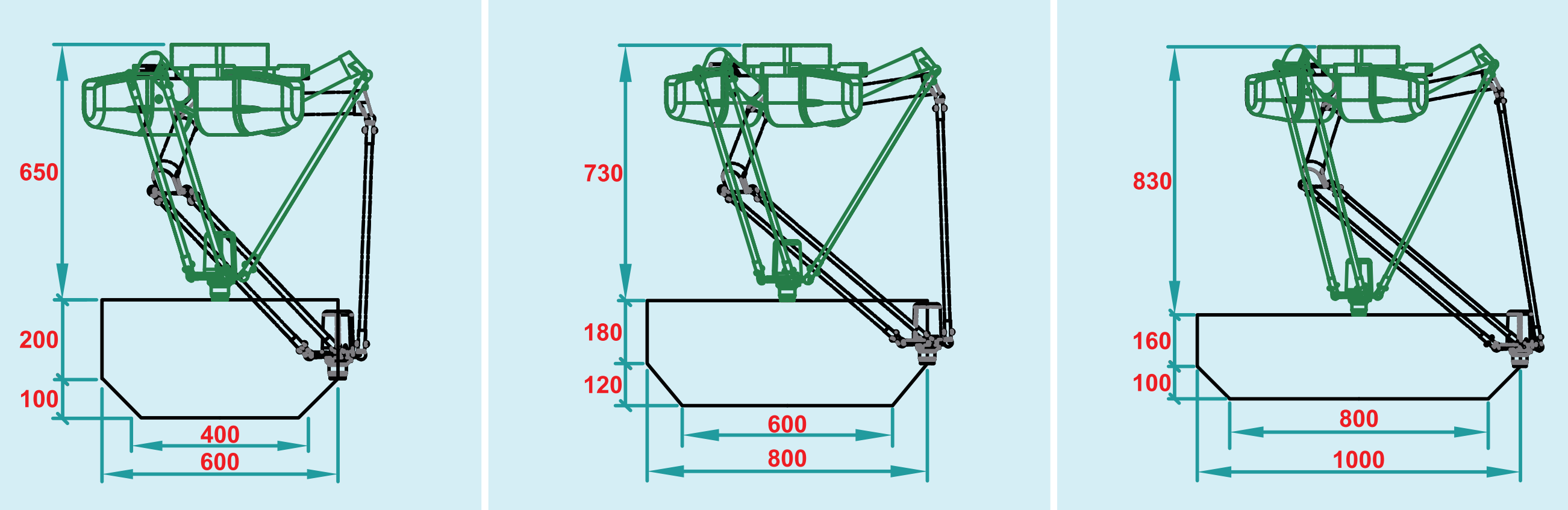

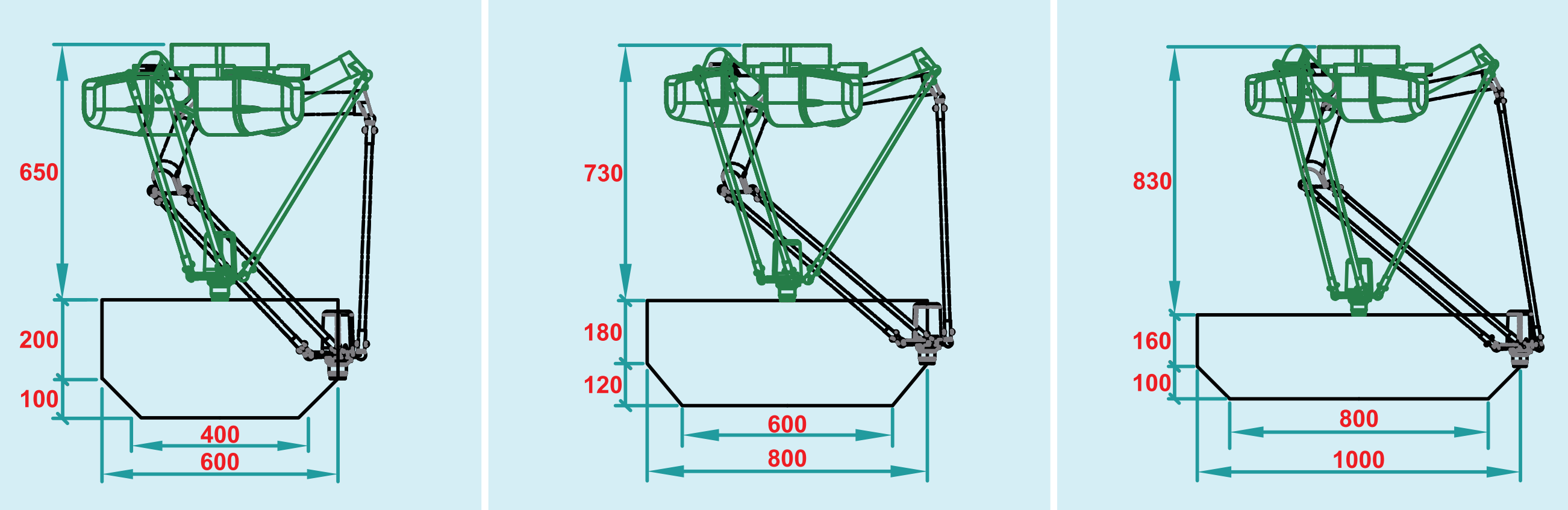

Working Range(mm)

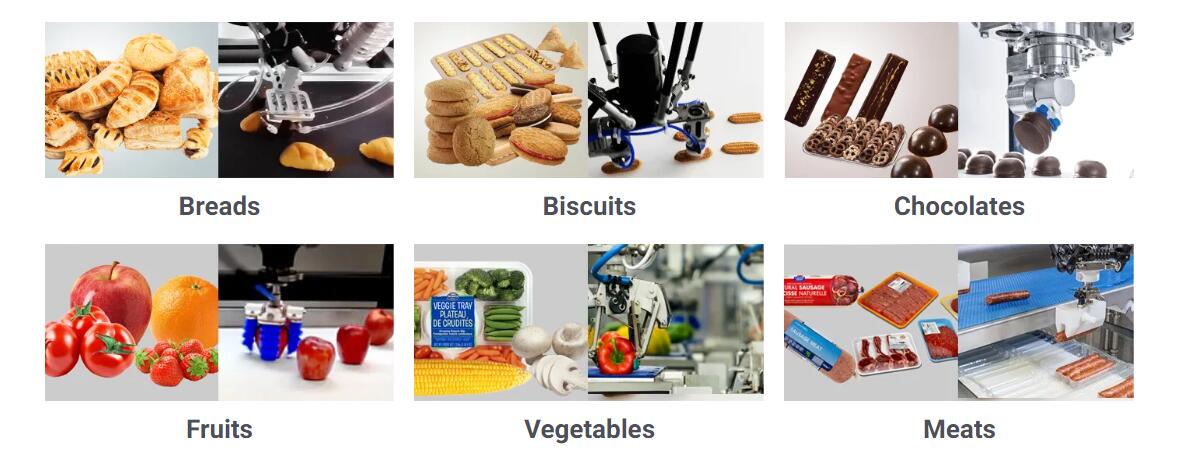

Applications:

✔ Food and Beverage Industry: Ideal for high-speed, precision packing and sorting of food and beverage products, maintaining quality standards and optimizing production efficiency.

✔ Pharmaceutical Sector: Ensures accurate and safe handling of pharmaceutical products, adhering to stringent regulatory requirements and protecting product integrity.

✔ Consumer Electronics: Efficiently manages the assembly and packaging of electronic components, enhances productivity and reducing handling times in electronics manufacturing.

✔ Logistics and Warehousing: Streamlines the sorting and packing process in distribution centers, contributing to better space utilization and faster operations.

Features

✔ High-Speed Performance: Capable of achieving speeds of up to 120 packs per minute (PPM), ensuring rapid and efficient processing in high-demand production lines.

✔ Cost-Effective Solution: Designed to provide superior performance at a competitive price point, offering excellent value for a wide range of industrial applications.

✔ User-Friendly Operation: Features an intuitive control interface that simplifies operation, allowing for quick setup and minimal training requirements.

✔ Modular System: The modular design allows for easy integration into existing production lines and flexible adaptation to changing production needs.

✔ Low Maintenance: Built for durability with minimal maintenance requirements, ensuring long-term reliability and reduced downtime.

✔ Certified Quality: ISO and CE certifications guarantee compliance with international standards, ensuring safety, quality, and reliability.

✔ Versatile Applications: Suitable for a wide range of industries, including food and beverage, pharmaceuticals, and consumer electronics, providing flexibility across multiple sectors.

✔ Warranty and Support: Comes with a 1-year warranty and free lifelong technical support, offering peace of mind and ongoing assistance.

✔ Advanced Communication Protocols: Supports multiple communication protocols, including Modbus TCP/P, EtherCAT, CAN, and RS232/485, ensuring seamless integration with various control systems.

Specifications

PARAMETERS

| Model |

WSC-600DJ-L3 |

WSC-800DJ-L3 |

WSC-1000DJ-L3 |

| Power Rating |

four-axis |

four-axis |

four-axis |

| Max Load(kg) |

3kg |

3kg |

3kg |

| Standard Cycle Time(s) |

0.4 seconds/cycle (25/305/25mm) |

0.4 seconds/cycle (25/305/25mm) |

0.4 seconds/cycle (25/305/25mm) |

| Repeat Positioning Accuracy(mm) |

±0.05mm |

±0.05mm |

±0.05mm |

| Angular Positioning Accuracy |

0.05° |

0.05° |

0.05° |

| Power |

220V-240v 50/60Hz |

220V-240v 50/60Hz |

220V-240v 50/60Hz |

| Power Rating |

2.5kw |

2.5kw |

2.5kw |

| Noise Level |

<75db |

<75db |

<75db |

| Protection Level |

IP54 |

IP54 |

IP54 |

| Motor Method |

AC servo drives |

AC servo drives |

AC servo drives |

| Demonstrator |

7-inch demonstrator |

7-inch demonstrator |

7-inch demonstrator |

| Vision Positioning Module |

Optional configuration (130W camera, lens, light Source) |

Optional configuration (130W camera, lens, light Source) |

Optional configuration (130W camera, lens, light Source) |

| Operating Instructions |

PTP, LINE, PICK, PLACE |

PTP, LINE, PICK, PLACE |

PTP, LINE, PICK, PLACE |

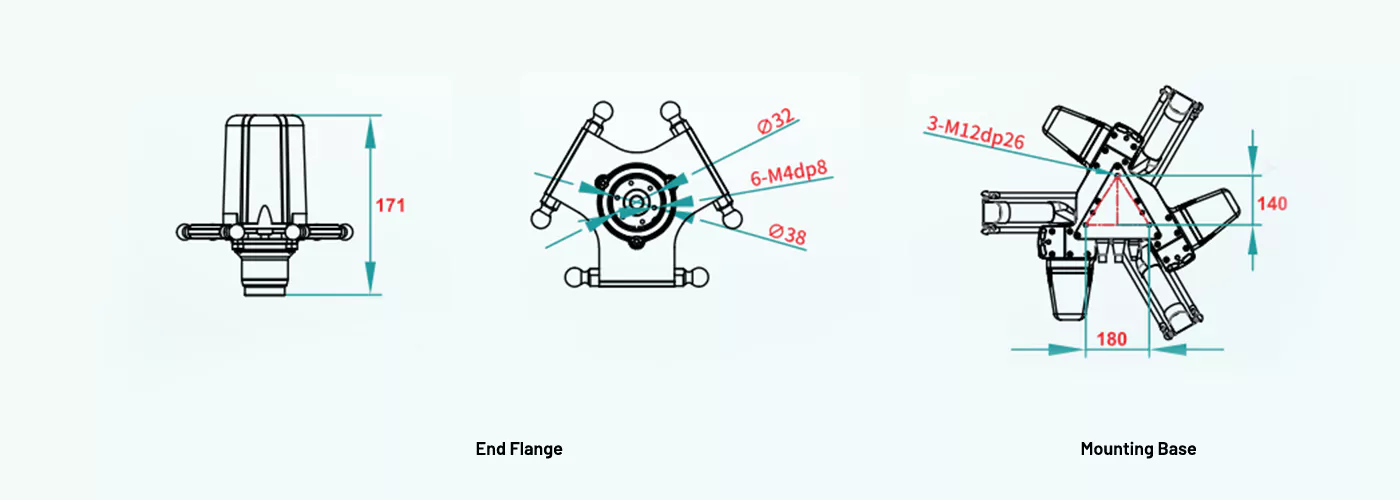

| Installation Method |

Inverted |

Inverted |

Inverted |

| Robot Weight |

40kg |

40kg |

40kg |

| Playlay load 0.1kg |

0.34s |

| Playlay load 1kg |

0.38s |

| Working Temperature |

1-40°C |

| Humidity Range |

5%~90%(No condensation) |

| Life Span |

20000 hours+ |

| GW |

40kg |

| 1-3rd Axis Motor (if) |

Panasonic |

| The Fourth Axis motor (then) |

Panasonic |

| 1-3rd Axis Reducer/Gearbox(if) |

Harmonic/Nidec |

| The Fourth Reducer/Gearbox(then) |

Leader drive |

| Controller/PLC |

Keba |

| HMI |

Keba |

Search

18046987606

18046987606

Fiona@Robobeen.com

Fiona@Robobeen.com