-

Search

-

18046987606

Fiona@Robobeen.com

Choosing the Right Collaborative Palletizer for Your Industry

Transforming Effectiveness with Safe Automation with Collaborative Palletizer:

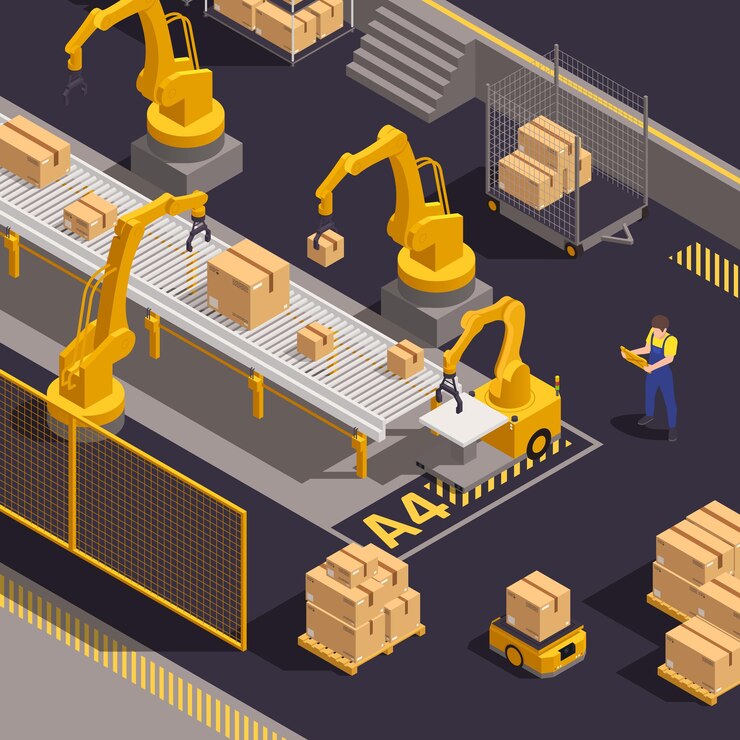

In the current complex society, organizations are always keen on looking forward to adopting means of efficiency, increasing production, and enhancing employees’ safety. That is why one of the most efficient solutions regarding this issue is the collaborative palletizer. Being a part of the latest trends in palletizing automation, this remarkable machine is built by combining the collaboration of humans and robots along with the help of recent technologies.

What is Meant by Collaborative Palletizer?

A collaborative palletizer is a sort of palletizer that integrates robotics using human operators. These machines are safe as compared to the conventional robots that are used in industries and production lines. Cobots are safe, strong and close to human interaction which can easily be adapted to perform the following tasks palletizing, thus making it suitable for industries that seek to automate their operations while still involving people. Among the most important characteristics that define palletizers are their compactness and low weight, which open broad opportunities for integration with already existing production environments. They also feature high-end sensors and safety features which make them safe to interact with human workers, which makes the human-robot interaction seamless.

Innovative Features Designed to Maximize Efficiency

The Collaborative Palletizer stands out with a range of features designed to maximize efficiency and safety in various industries:

International First-Class Heavy-Load Cooperative Robot: With this wooden frame construction, this palletizer is designed to handle both big and bulky goods since it is robust enough to withstand tough operations in production lines.

Portable Mobile Base: The mobile base of the palletizer makes it easy to move or reposition within the workspace making it convenient yet very efficient in its operations.

7th Axle Lifting Column: This palletizer has a 7-axle lifting column that can help it to move vertically and it makes it easy for the palletizer to position products perfectly without strain.

End Effector: The end effector is light in weight and has very high suction capacity and anti-drop technology to prevent the dropping of the products.

Large Suction and Anti-Dropping Patented Products: Equipped with patented features, collaborative palletizer provides a minimal risk of dropping the products thereby enhancing the product’s stability.

Card Positioning System: This is because the card positioning system is incorporated in the design, hence improving efficiency in product alignment that enhances palletizing.

Why Choose a Robobee Collaborative Palletizer?

In Robobee, our collaborative palletizer is adopted extensively in the food, pharmaceutical, daily chemical, and electronics industries. Whether you are only looking for an easy modification to make your palletizing even better or looking for a more complicated setup that is part of more extensive automation, we’ve got you covered. The team of specialists will provide you with professional assistance and will direct you to the most suitable product. Being flexible, safe and productive, our cobot palletizers have been created to fit all the requirements of your business and help save time and money.

Safety:

Specifically, cobots are outfitted with the latest in safety technology such as programmable sensors and force-sensitised tools that guarantee the safety of the palletizing process alongside human employees. This reduces instances where your workers get injured hence increasing safety in your workplace.

Efficiency:

There is an elaborate and positive correlation between collaborative palletizers and the corresponding speed and total efficiency of resulting palletizing jobs. They further provide quick execution of cyclic repetitive operations without compromising on fatigue hence enhancing productivity.

Cost-Effective:

Implementing an automation solution in your palletizing process can greatly cut your expenses through; minimizing the workforce needed, avoiding incidences in a workplace hence.

Flexibility:

Generally, Palletizers are designed to efficiently accommodate various types of products and thus provide elastic palletizing systems. This makes them ideal for an industry that often has to package different products and this includes the food and beverages and pharma industries among others.

Easy-to-Use:

Another major advantage of a collaborative palletizer is the ability of the latter to operate with a simple interface. Due to the minimal training of the operator, the palletizer can be programmed and managed without the need for extensive training hence increasing productivity.

Robobee is the Collaborative Palletizer Supplier:

Robobee is a top manufacturer of palletizers and it is given to provide the best solutions to companies that would require the services of palletizers. As collaborative robots intended to improve the productivity and safety of different industries such as manufacturing, food and beverage, and logistics, Robobee palletizers are prepared to minimize the expenses of the companies.

- The palletizers are designed collaboratively with integrated technologies; they encompass capabilities of handling heavy loads, mobile base, and 7th axle lifting columns for vertical actions. These palletizers also incorporate patented suction technology and anti-dropping systems to keep the products safe when transferring them.

- As a reliable Collaborative Palletizer partner, Robobee offers non-integrated, easy-to-implement and integrated solutions in any manufacturing line. Regardless of whether your company is a small enterprise or a big corporation, our cobot palletizers are targeted for your business needs and general efficiency is bound to enhance.

How to Choose the Right Collaborative Palletizer?

When choosing a palletizer for your business, some considerations need to be put into consideration. Here are some key points to keep in mind:

Industry-Specific Needs: You should then go for a palletizer that has been specially designed to handle your type of industry. For instance, if you are involved in the handling of drugs in a pharmaceutical firm, you should consider a palletizer with precision handling.

Load Capacity: Make sure that a specific palletizer can bear your products’ weight and size. Automotive palletizers may well have higher load capacities than palletizers in the food and beverage industry.

Safety Features: When choosing palletizers, one should focus on the safety features of the palletizers especially if the palletizers are to be positioned close to the human operators. Force-limited technology utilized by cobots guarantees safe physical interfaces with human resources.

Conclusion:

Our palletizer into your operations can significantly improve your business’s efficiency, safety, and productivity. With our cost-effective, flexible, and easy-to-use nature, these palletizers are suitable for a wide range of industries, from food and beverage to logistics. As automation continues to evolve, adopting collaborative technologies will give your business a competitive edge. So, if you’re looking to boost your production, consider investing in a palletizer today. For more information on collaborative palletizer, visit our RoboBee and explore the various solutions we offer to help your business thrive.