-

Search

-

18046987606

18046987606

Fiona@Robobeen.com

Fiona@Robobeen.com

Overview

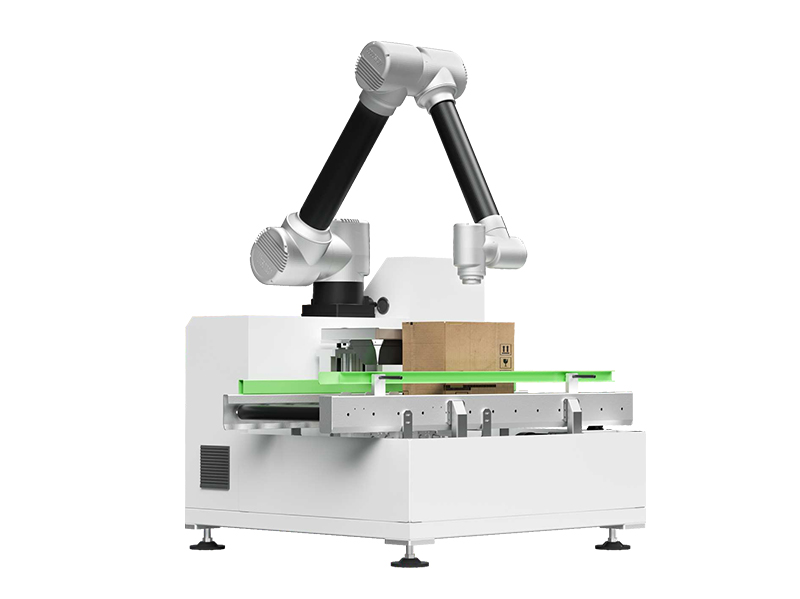

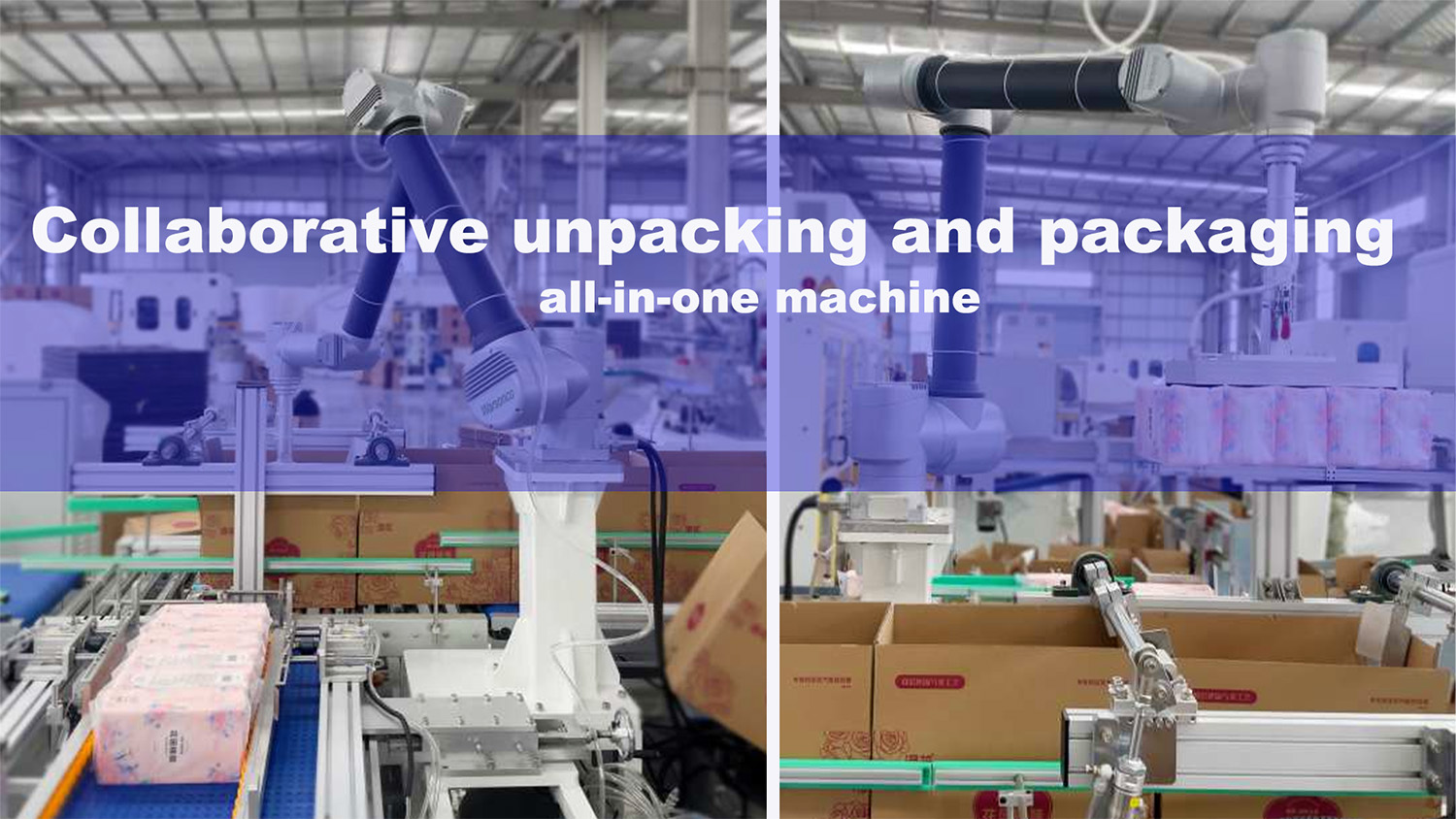

The Case Packer Robot UP 16KG-40KG-WSC-ZX-XZ25 is an advanced automated solution designed to optimize and streamline the packaging process for heavy-load applications. Engineered to handle products ranging from 16kg to 40kg, this robust robot excels in high-efficiency packing, sorting, and orientation tasks, making it an invaluable asset in modern manufacturing and logistics environments. Its cutting-edge technology integrates multiple functions into a single system, delivering exceptional performance while reducing manual labor and enhancing productivity.

This sophisticated case packer robot is built with a focus on reliability and precision, ensuring consistent and accurate packing of heavy products. It supports various packing requirements with its versatile design, making it ideal for industries that demand high-load handling and efficient workflow management.

Applications

✔ Manufacturing Facilities: Ideal for automating the packing of heavy products in high-volume production environments, improving efficiency and reducing labor costs.

✔ Distribution Centers: Streamlines the packing and sorting of products, facilitating smooth transitions from production to distribution.

✔ Food and Beverage Industry: Handles the packing of heavy food and beverage products, ensuring adherence to hygiene standards and operational efficiency.

✔ Pharmaceutical Sector: Efficiently packs heavy pharmaceutical products, maintaining compliance with industry regulations and standards.

✔ Consumer Goods: Optimizes the packing of heavy consumer goods, including electronics and household items, to enhance productivity and streamline workflows.

✔ Logistics and Warehousing: Facilitates the efficient packing and sorting of goods in warehouses, contributing to better space utilization and operational effectiveness.

| Configuration | |

| Servo Driver | Warsonco |

| Controller | Keba |

| Reducer | Laifual |

| Pneumatic System | Air TAC |

Features

✔ High-Load Handling: Designed to accommodate products weighing between 16kg and 40kg, ensuring reliable performance in heavy-load applications.

✔ Advanced Robotic Technology: Utilizes state-of-the-art robotics for precise packing, sorting, and orientation, enhancing overall efficiency in the production line.

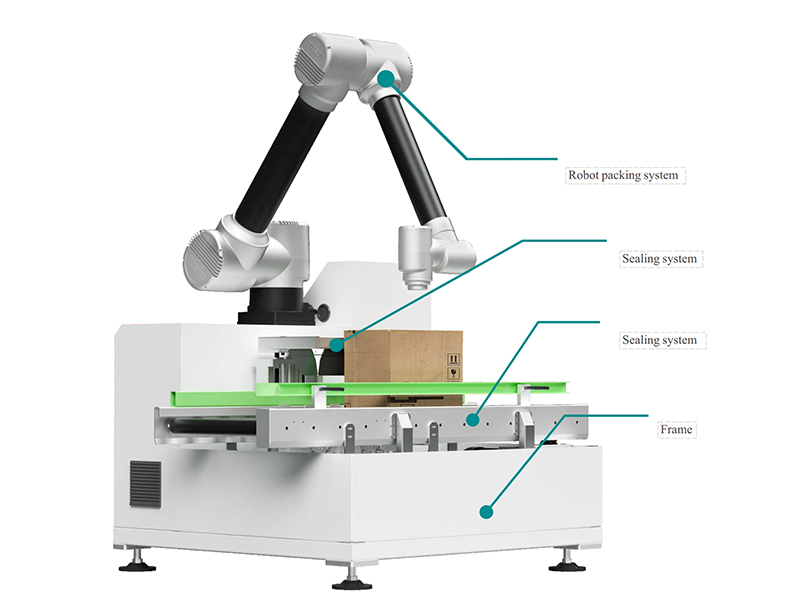

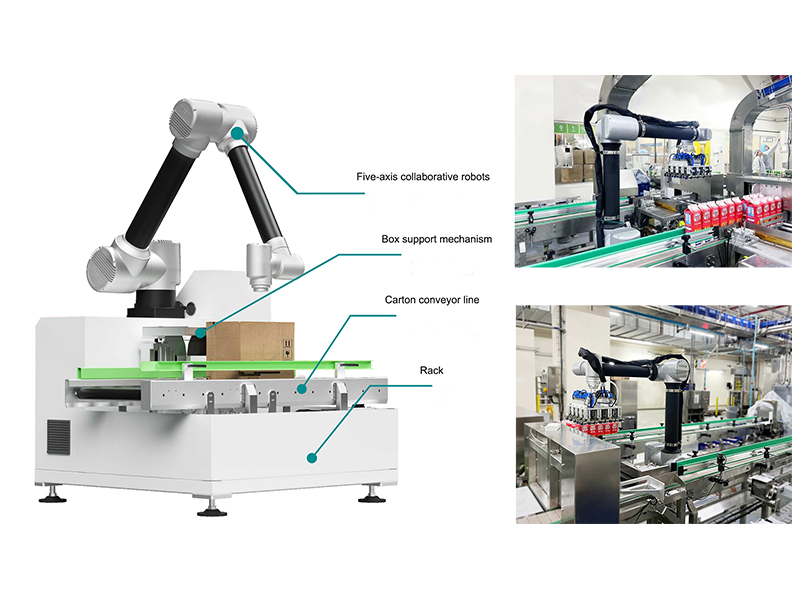

✔ Integrated System: Combines multiple functions including case forming, product packing, and bottom sealing into a single automated process, reducing the need for manual intervention.

✔ User-Friendly Interface: Equipped with an intuitive control interface that allows for easy operation and monitoring of the robot’s functions.

✔ Durable Construction: Features a robust design with high-quality materials to withstand the demands of heavy-load operations and ensure long-term reliability.

✔ Flexible Case Sizes: Supports various case sizes and dimensions, accommodating a wide range of packaging needs.

✔ Efficient Sorting and Orientation: Ensures accurate and efficient sorting and orientation of products, improving the overall packing process.

✔ Speed and Precision: Capable of high-speed packing with precise placement, enhancing productivity and reducing errors in the packaging process.

Specifications

| Collaborative packing machine | |||

| Packing Speed | 6-8 cases/min | Total Weight | 1000kg |

| Maximum Power | 3.5kw | Rated Load | 25kg(with out robot gripper) |

| Dimension | L1635mm*W1244mm*H2020mm | Collaborative Robot | WSC-XZ30 |

| Applicable Product Size | L(50-300)mm*W(50-280)mm*H(35-100)mm | ||

| Applicable Carton Size | L(280-500)mm*W(150-400)mm*H(150-400)mm | ||

| Applicable Industries | Pharmaceutical, daily use chemical, food and other industries | ||

| Main Material | Stainless steel SUS 304/White baking paint Q 235 | ||